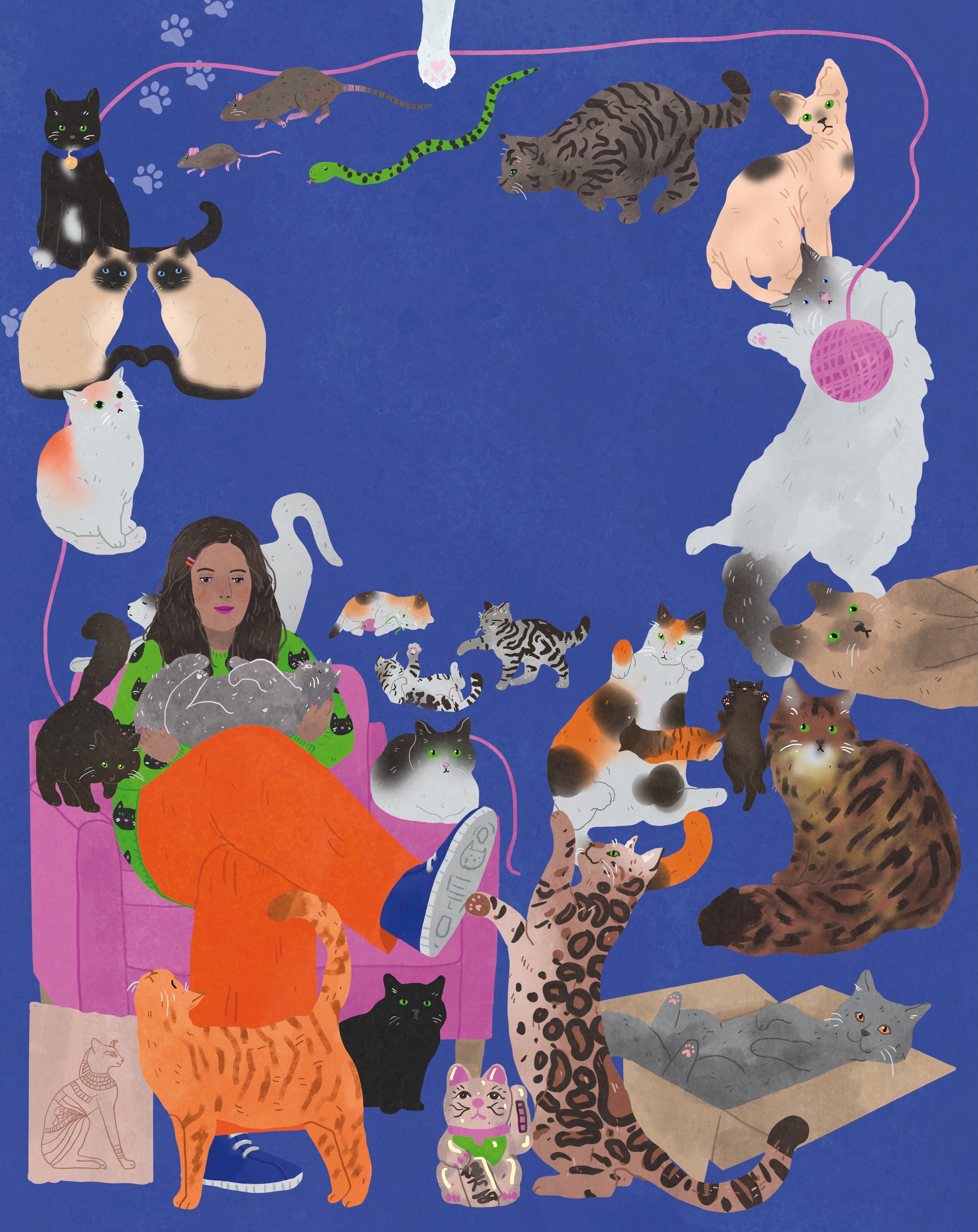

The ancient art of cat fiction is enjoying a resurgence in the UK. If you’ve missed it so far, here’s all you need to kniaow

Japanese cat fiction, also known as ‘healing fiction’ and ‘cosy fiction’ if you’re looking for it in book shops had a long history, dating back more than a thousand years.

They’re whimsical, comforting stories that provide escapism and generally feature bookshops, libraries, coffee houses… and cats, obviously. They’re usually contemporary and set in Japanese cityscapes but often have a magic-realist or time-travel element to them.

The first piece of Japanese cat fiction is arguably The Tale of Genji by Murasaki Shikibu, written in the early 11th century, and is quite likely the world’s first novel, too, so definitely set a trend.

In modern terms, however, it was I Am A Cat by Soseki Natsume published in 1905 and in English in 1961 that really kick-started the healing/cosy/cat genre. I Am A Cat eventually spawned ten books in the series.

In the last few years, you may have noticed Japanese cat fiction piling up on bookshops’ ‘recommended’ tables with titles such as We’ll Prescribe You A Cat and Days At The Morisaki Bookshop flying off shelves in the UK. And with our long, cold winters, frankly we don’t know how we’ve done without books about cats in bookshops and coffee shops for so long.

5 Japanese Cat Books to get you started

I Am A Cat by Natsumi Soseki

The Cat Who Saved Books by Sosuke Natsukawa

The Travelling Cat Chronicles by Hiro Arikawa

The Kamogawa Food Detectives by Hisashi Kashiwai

If Cats Disappeared From The World by Genki Kawamura

If you’d like to read more about cats in culture, you might enjoy our February issue’s ‘Know A Thing or Two’ feature by Iona Bower, which is all about cats. The issue is in shops now and available from our online store.

Buy this month's The Simple Things -buy, download or subscribe